Time:2024-10-19 Views:0

Energy efficiency standards for power adapters are crucial in reducing energy consumption and environmental impact. These standards vary across different regions and are continuously evolving to meet the growing demand for energy conservation.

In the United States, the Department of Energy's Level VI efficiency regulations are in effect. This standard, which became mandatory from February 2016, has set strict requirements for the minimum average efficiency of external power supplies in active mode and the maximum input power consumption during standby mode. It subsumes many of the European Code of Conduct (CoC) Tier 1 regulations. The Level VI standard aims to ensure that power adapters operate more efficiently, minimizing energy waste not only during normal use but also when the device is not in active use but still connected to the power source.

In the European Union, there are also specific energy efficiency standards such as the Ecodesign 2019/1782 regulations. These regulations focus on reducing the energy consumption of electrical and electronic products, including power adapters. The EU standards take into account various factors such as the efficiency of the power conversion process, standby power consumption, and the power factor. A higher power factor indicates that the power adapter draws current more in phase with the voltage, reducing the impact on the power grid and improving overall energy efficiency.

Internationally, the International Electrotechnical Commission (IEC) also plays a significant role in formulating energy efficiency standards for power adapters. The IEC standards provide a common framework for manufacturers to design and produce power adapters that meet the energy efficiency requirements of different countries and regions. For example, the IEC 62368 standard is relevant for power adapters used in audio, video, information, and communication technology equipment, and it includes requirements related to energy efficiency.

To meet these energy efficiency standards, power adapter manufacturers need to adopt advanced technologies and materials. This may include the use of more efficient switching power supply circuits, high-quality capacitors and inductors, and improved transformer designs. Additionally, optimizing the control algorithms of the power adapter can help to enhance its efficiency across different load conditions.

Read recommendations:

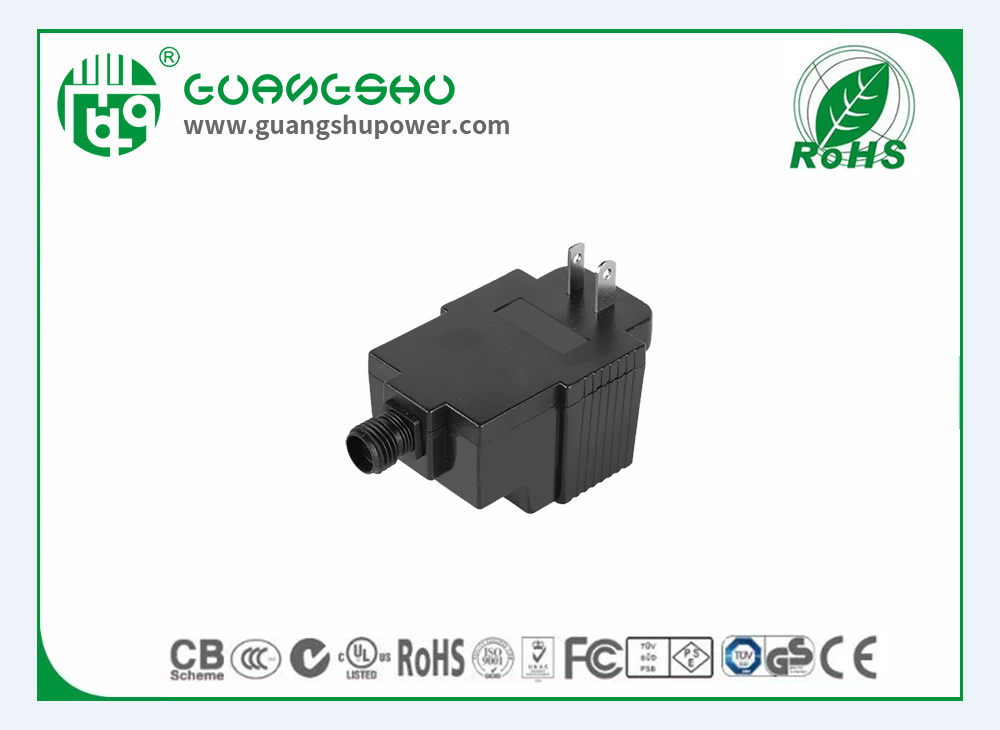

63W European Plug Switching power supply