Time:2024-10-10 Views:0

Dust - proof and sealed power adapters are specifically designed to operate in environments where dust and other contaminants could potentially affect their performance or cause damage. These adapters are essential in various industrial, outdoor, and even some domestic applications.

In industrial settings, such as factories, construction sites, and mines, there is a high concentration of dust particles in the air. A dust - proof and sealed power adapter can prevent these dust particles from entering the internal components of the adapter. Dust can be a significant problem as it may accumulate on the circuit boards, heat sinks, or other components. Over time, this accumulation can lead to overheating, short - circuits, or interference with the electrical connections. For example, in a metal - working factory, metal dust can be conductive and if it gets inside the power adapter, it may cause short - circuits between different electrical parts.

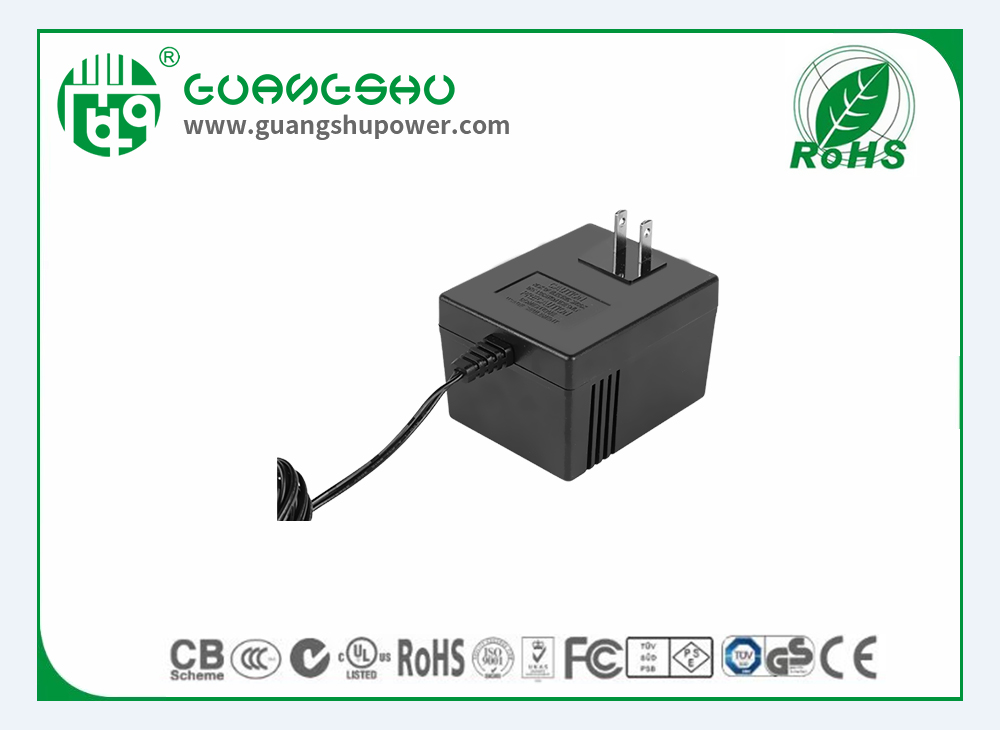

The sealing of the power adapter is achieved through the use of high - quality gaskets and enclosures. These enclosures are made of materials that are both durable and resistant to dust penetration. For example, some power adapters use plastic or metal enclosures with rubber gaskets around the seams and openings. This creates a tight seal that keeps dust out while still allowing for proper ventilation if required.

Outdoor applications also benefit from dust - proof and sealed power adapters. For example, in outdoor lighting systems, power adapters are exposed to the elements, including dust, dirt, and moisture. A sealed power adapter can prevent dust from clogging the internal components and also protect against moisture ingress, which can cause corrosion. In addition, in some domestic applications where the environment may be dusty, such as in a workshop or garage, these power adapters can ensure reliable operation.

Dust - proof and sealed power adapters also often have additional features to enhance their performance in such environments. For example, they may have better heat dissipation mechanisms that are designed to work effectively even when sealed. This is important because the prevention of dust ingress should not come at the cost of overheating. Additionally, they may be more rugged in design to withstand physical impacts and vibrations that are common in industrial and outdoor settings.

Read recommendations:

12V12A 144W C14 Switching Power Supply